Pump maintenance and repair

Our pump repair services

With more than two decades of experience, we undertake the repair and maintenance of various industrial pumps, including vacuum pumps.

Our services include, among others:

- on-site dismantling

- transportation

- repair or complete renovation, and

- commissioning.

Experience and equipment

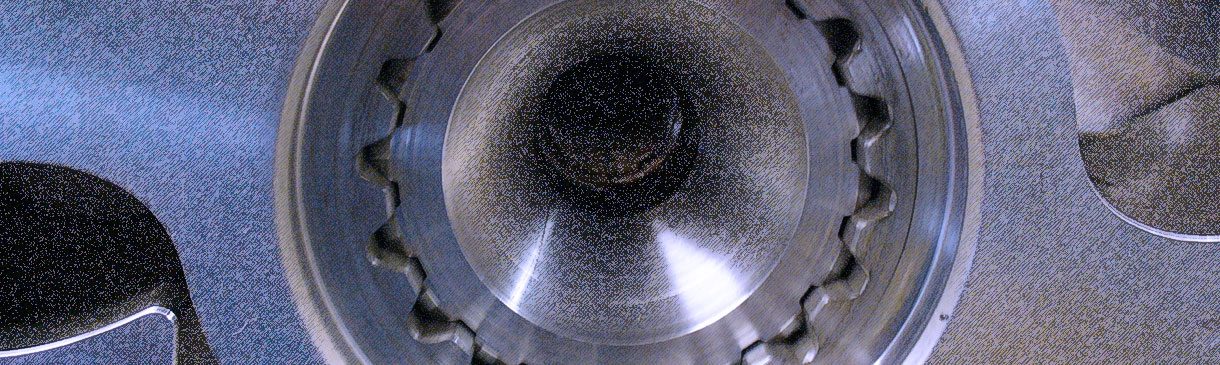

The first important goal of the repair process is to achieve comprehensive diagnostics. As part of this, we identify problems caused by wear, operational errors, or fatigue of material, and then remedy them by replacing parts or repairing surfaces. In most cases, it is essential to replace bearings, shaft seals, and other wear parts, as well as to repair or remanufacture shafts. This is followed by reassembly, and the refurbishment is completed with final inspections and rotation tests.

Eight mechanical ring-lapping machines assist us in our work of refurbishing pumps and stuffing box of mixing devices.

The equipment in our workshop, the expertise of our colleagues, and the diagnostic tools and instruments at our disposal enable us to repair pumps that will continue to operate reliably in the long term, subject to the necessary warranty conditions.

Our references in pump repair

Over the past 30 years, we have worked with the following pump types, among others:

- Busch,

- Edwards,

- Flowserve,

- Nash,

- Robuschi,

- SIHI, and

- Tuthill.

Our previous clients

Our previous clients include companies in the pharmaceutical, chemical, biotechnology, and food industries:

- TEVA Gyógyszergyár Zrt., Debrecen site: preventive maintenance of more than 2,500 pumps, troubleshooting unexpected failures,

- TEVA Gyógyszergyár Zrt., Gödöllő site: repair of pumps in the event of unexpected failures

- HUMAN Bioplazma Kft.: Repair of pumps and other equipment, provision of spare parts

- GlaxoSmithKline Biologicals Kft.: Repair of pumps in the event of failure, annual maintenance of mixing equipment, repair of faults discovered during maintenance