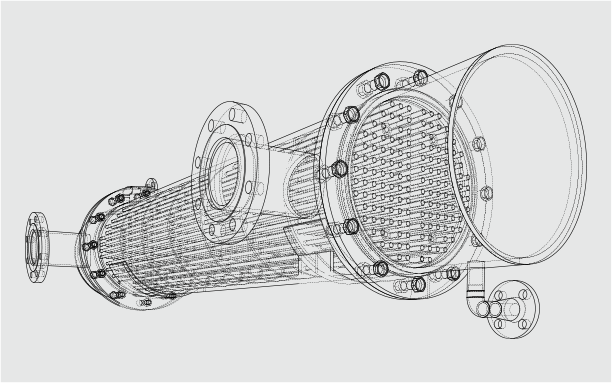

Manufacture of shell and tube heat exchangers

Manufacturing precision in heat exchangers

Proper thermal and strength design of shell and tube heat exchangers, followed by professional manufacturing based on these designs, is key to the efficient operation of heat exchangers.

User requirements and the physical and chemical properties and parameters of the media used in heat exchangers must be taken into account when selecting the raw materials needed to construct the heat exchanger.

Quality assurance at every step

The reliable operation of heat exchangers requires the precise execution of strict manufacturing processes and strict adherence to manufacturing technology operations.

All of this must be ensured:

- starting with the procurement of the raw materials required for the individual components,

- the preparation of the materials to be installed,

- the manufacture of the individual components,

- the assembly of sub-assemblies, and

- the welding and pressing operations,

- through to final assembly.

Gyémánt-Pirazol Kft.'s strict quality control system ensures that the finished product complies with the relevant industry standards and regulations.

Modern equipment plant, two manufacturing sites

We have all the human and machine resources, professional experience, and licenses that are essential for the professional manufacture of shell and tube heat exchangers. Thus, at both of our manufacturing sites—in Debrecen and Salgótarján—we have at our disposal, among other things:

- Highly experienced and certified welders, pipe fitters, fitters, and machinists

- Pipe end finishing, orbital pipe end welding, and pipe pressing machines

- Universal and CNC machine tools

- Professional material testing and quality control personnel and equipment

Quality assurance, certificates

We have the necessary certificates for the manufacture and material testing of heat exchangers as pressure equipment. In addition, we are also officially authorized to have our products certified by an independent third party (NoBo), to carry out the required tests and to prepare the relevant documentation.

Our manufacturer certificates:

- ISO 9001:2015,

- MSZ EN ISO 3834:2-2021,

- PED 2014/68/EU,

- AD2000 HP 0.

Our material inspection certificates:

- VT3,

- PT3,

- RT3,

- MT3,

- UT3.

Our experience in heat exchanger manufacturing

The performance and geometric dimensions of the heat exchangers we manufacture vary greatly. We manufacture both very small heat exchangers (with a heat transfer surface of one or two square meters) and huge ones (with a heat transfer surface of several hundred square meters). The latter may involve the threading, pressing, and welding of several thousand pipes.

Even the manufacture of low-power shell-and-tube heat exchangers demand a high level of expertise, strict professional and technological discipline, and very advanced quality assurance at every stage of the technological process.

Over the decades, we have mastered all the manufacturing processes necessary to achieve the perfect end product:

- From the sequence of welding operations involving high heat input

- To the professional pressing of pipes

- Through professional final assembly

- To successful pipe and casing pressure tests.

Our references in the field of heat exchanger manufacturing

In recent years, we have manufactured and delivered several heat exchangers for foreign orders (e.g. to Aquagas Sweden AB) and for the domestic market (e.g. to Borsodchem Zrt., Láng Energetika Kft. and Euroapi Kft.).

We receive orders from all kinds of industries: from the hydrogen industry through heavy chemical industry to the pharmaceutical industry. To the general satisfaction of our customers, we continuously deliver custom-made heat exchangers without any quality issues.